Choosing a Mechanical Parts Manufacturer: What You Need to Know About CNC Machining!

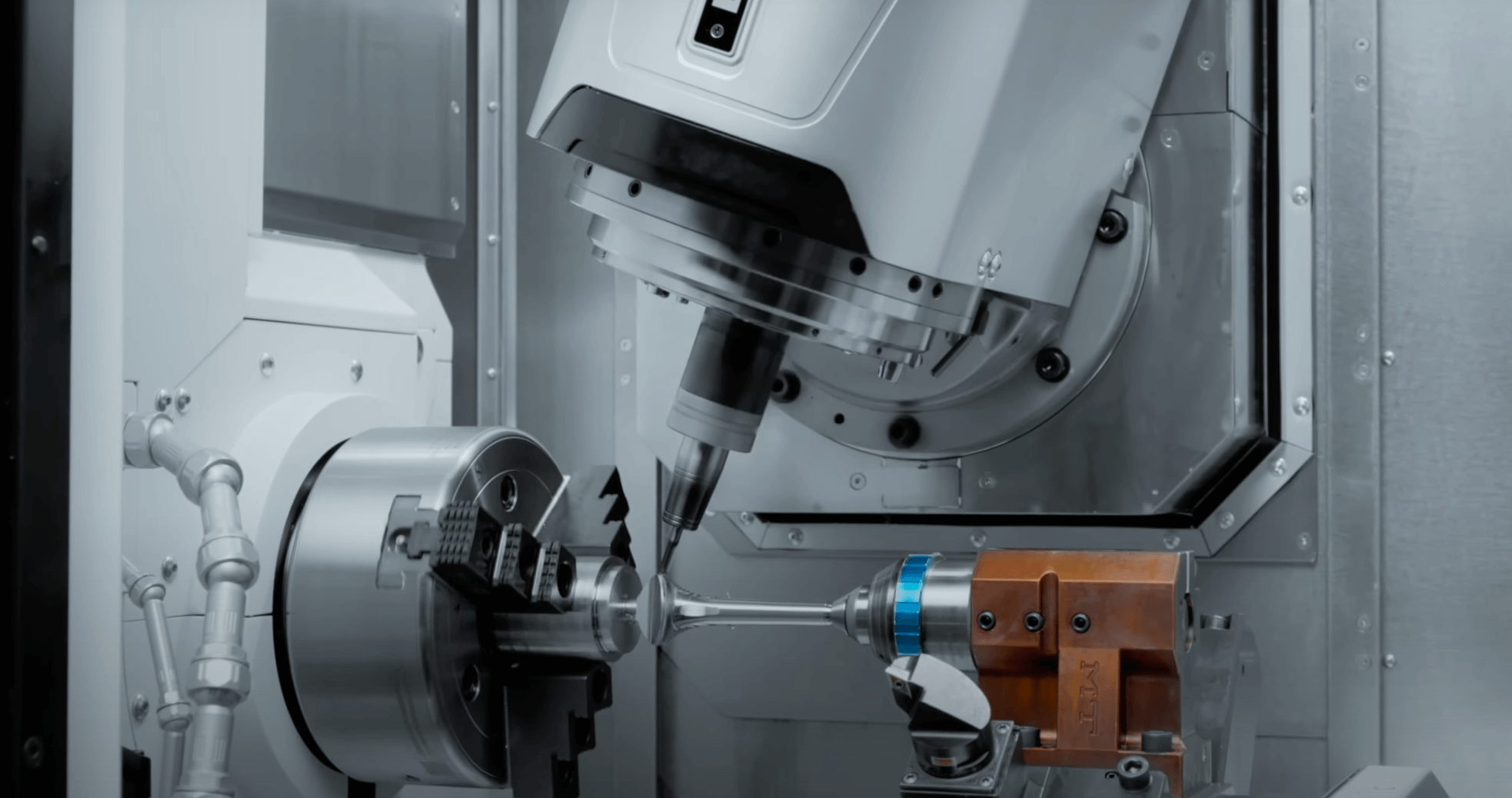

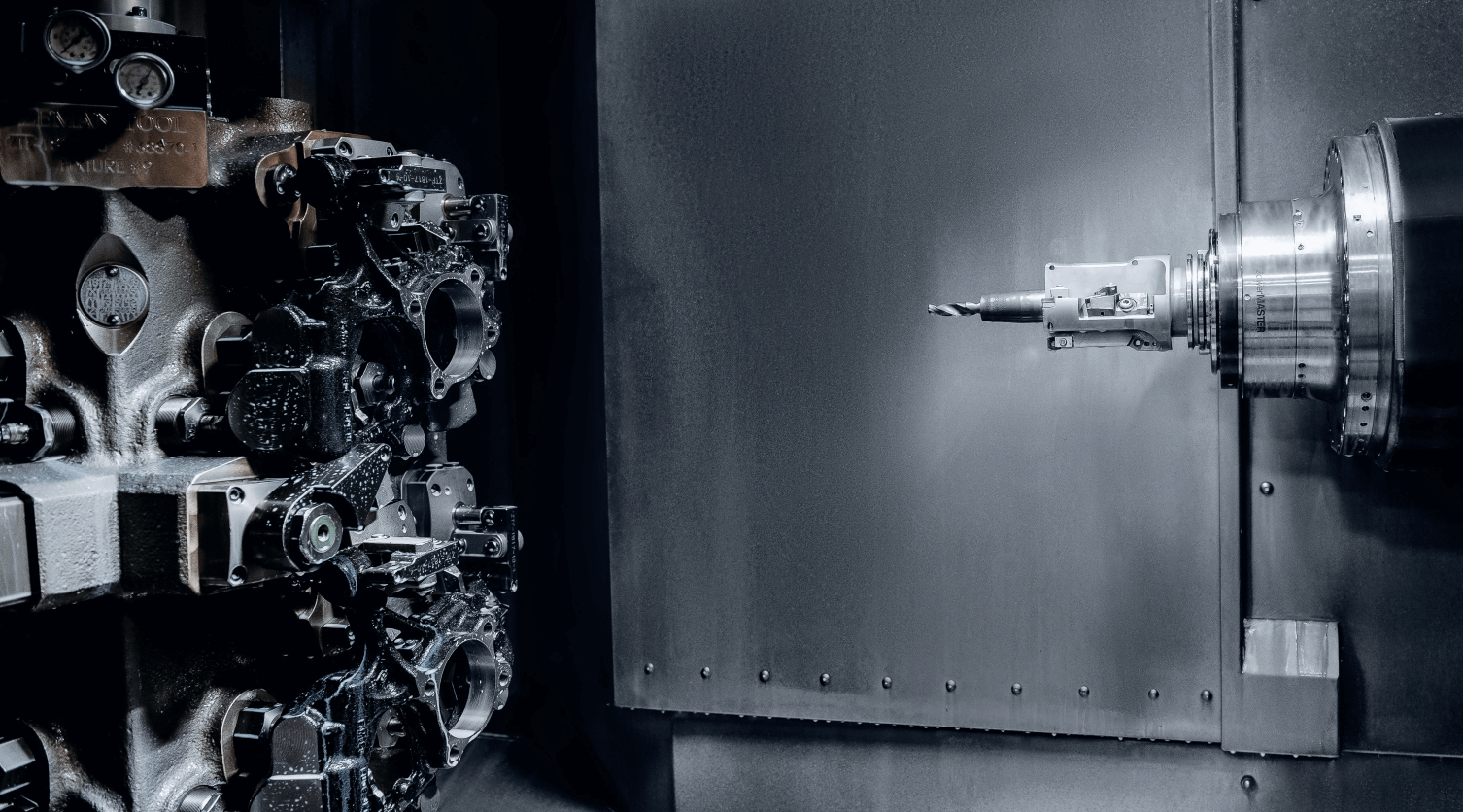

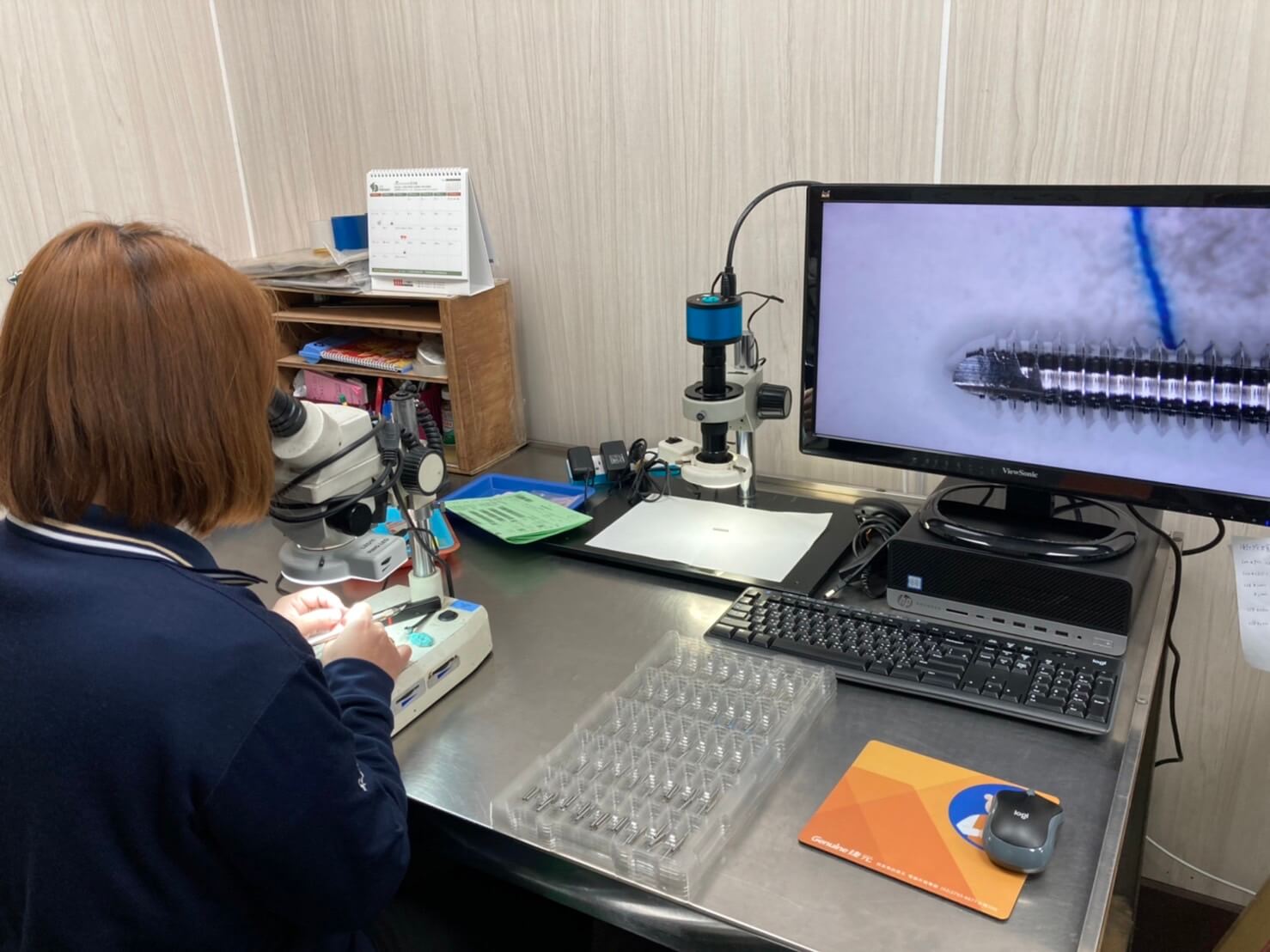

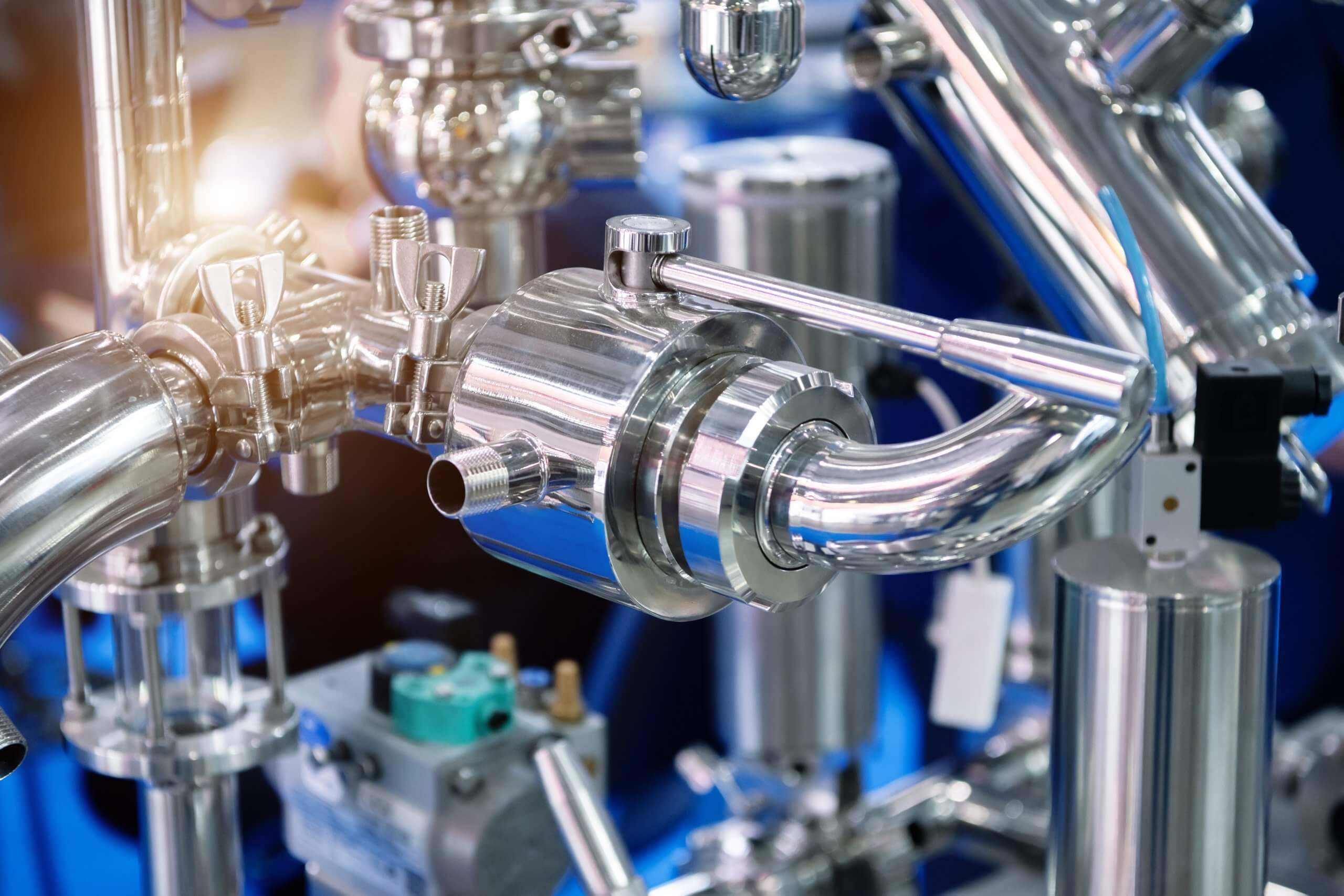

Mechanical parts play an indispensable role in the operation of machines. They form the cornerstone ensuring diverse functionalities within machines are realized. The precision and quality of these parts have a profound impact on machine performance, where each tiny detail directly influences the overall system’s operations.

Understanding Your Needs

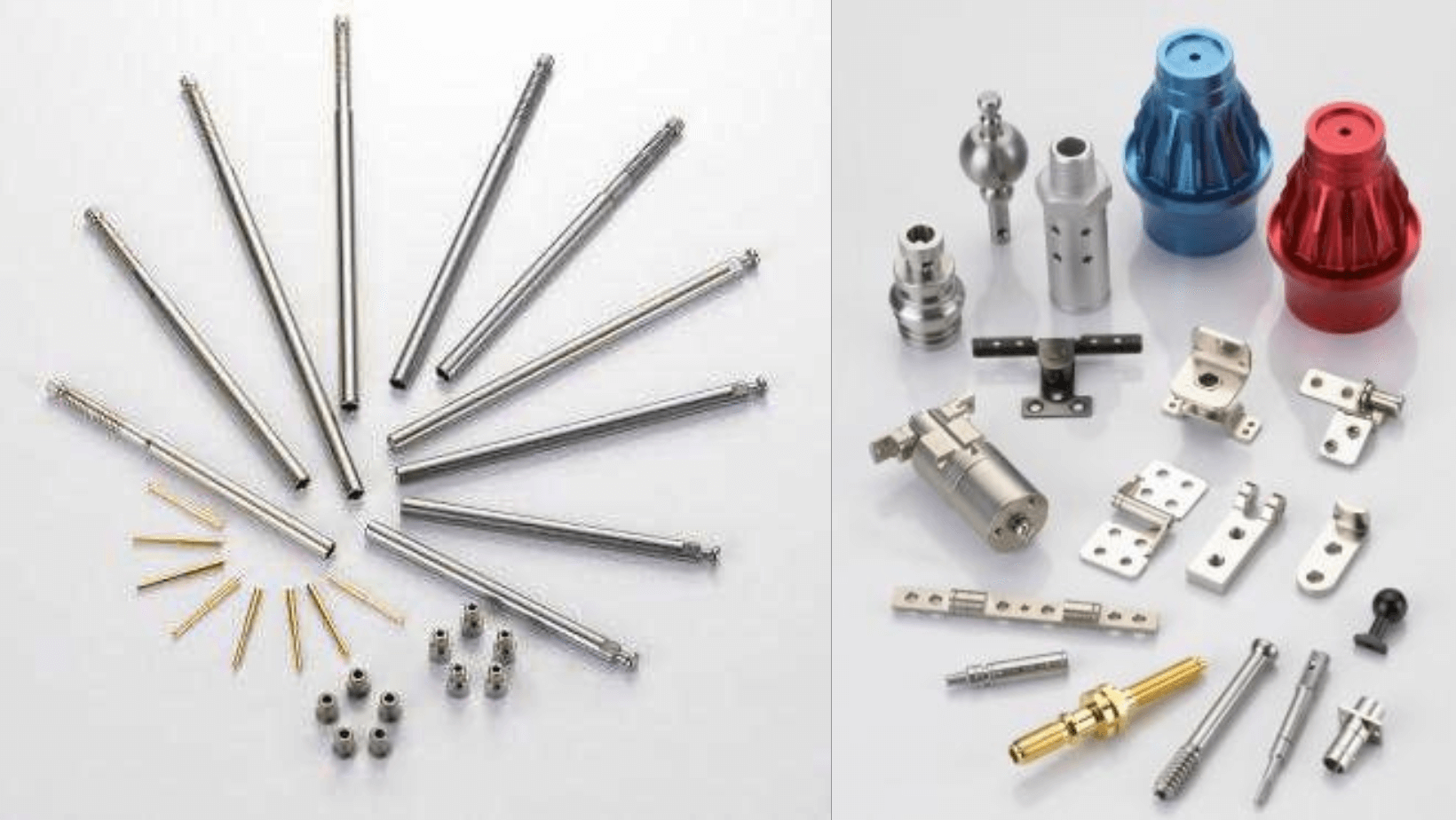

Universal Parts: These components, such as shafts, screws, nuts, gears, and connectors, are commonplace in machines. Their manufacturing requires adherence to standardized specifications, ensuring interchangeability and universality.

For universal parts, balancing price and machining quality is key!

Specialized Parts: Custom-manufactured for specific needs, these parts demand meticulous design and machining processes. Assessing the capabilities of a skilled CNC technician is crucial, as specialized designs may necessitate re-evaluation for effective production.

When seeking specialized parts, a manufacturer’s design expertise and technical knowledge become pivotal.

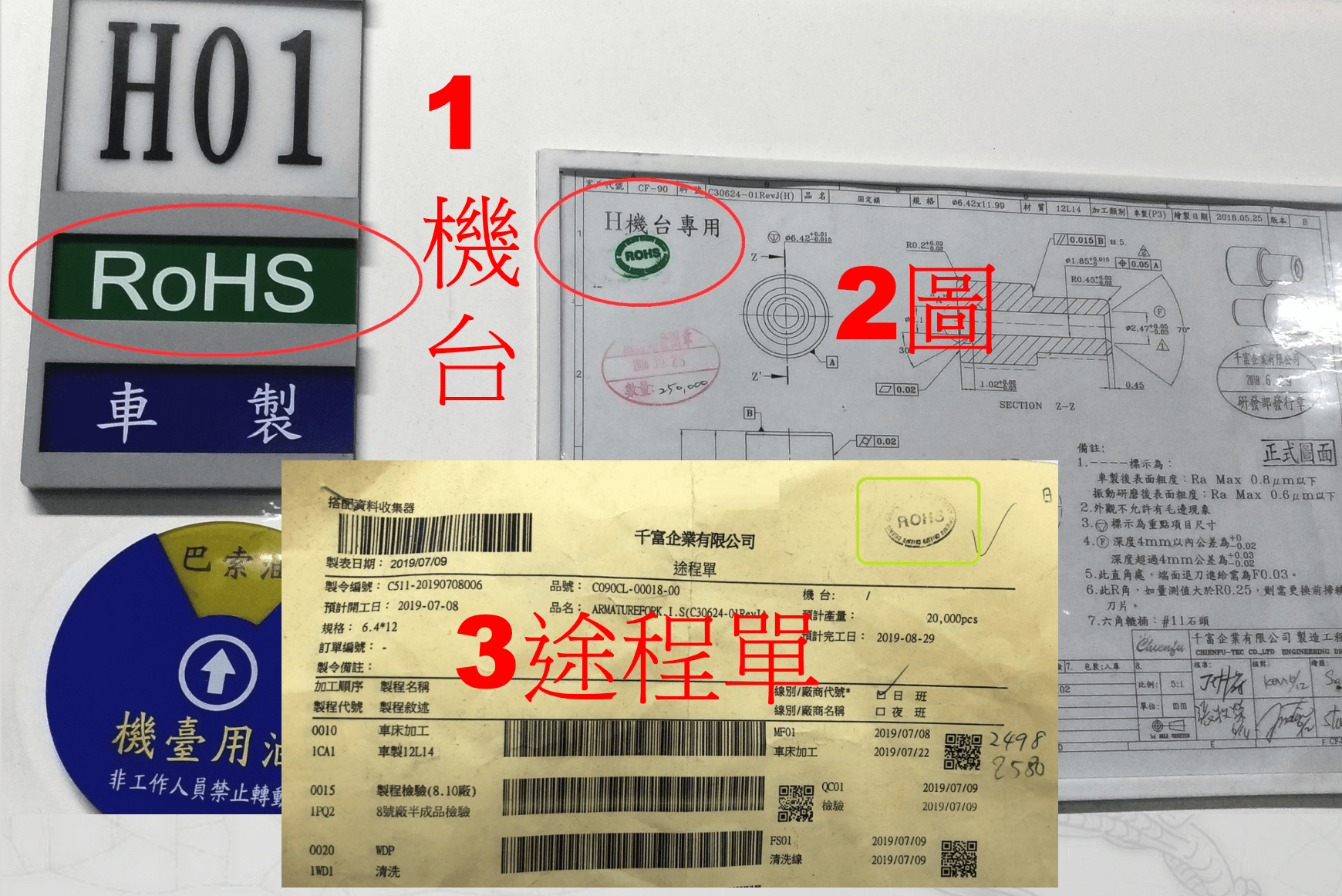

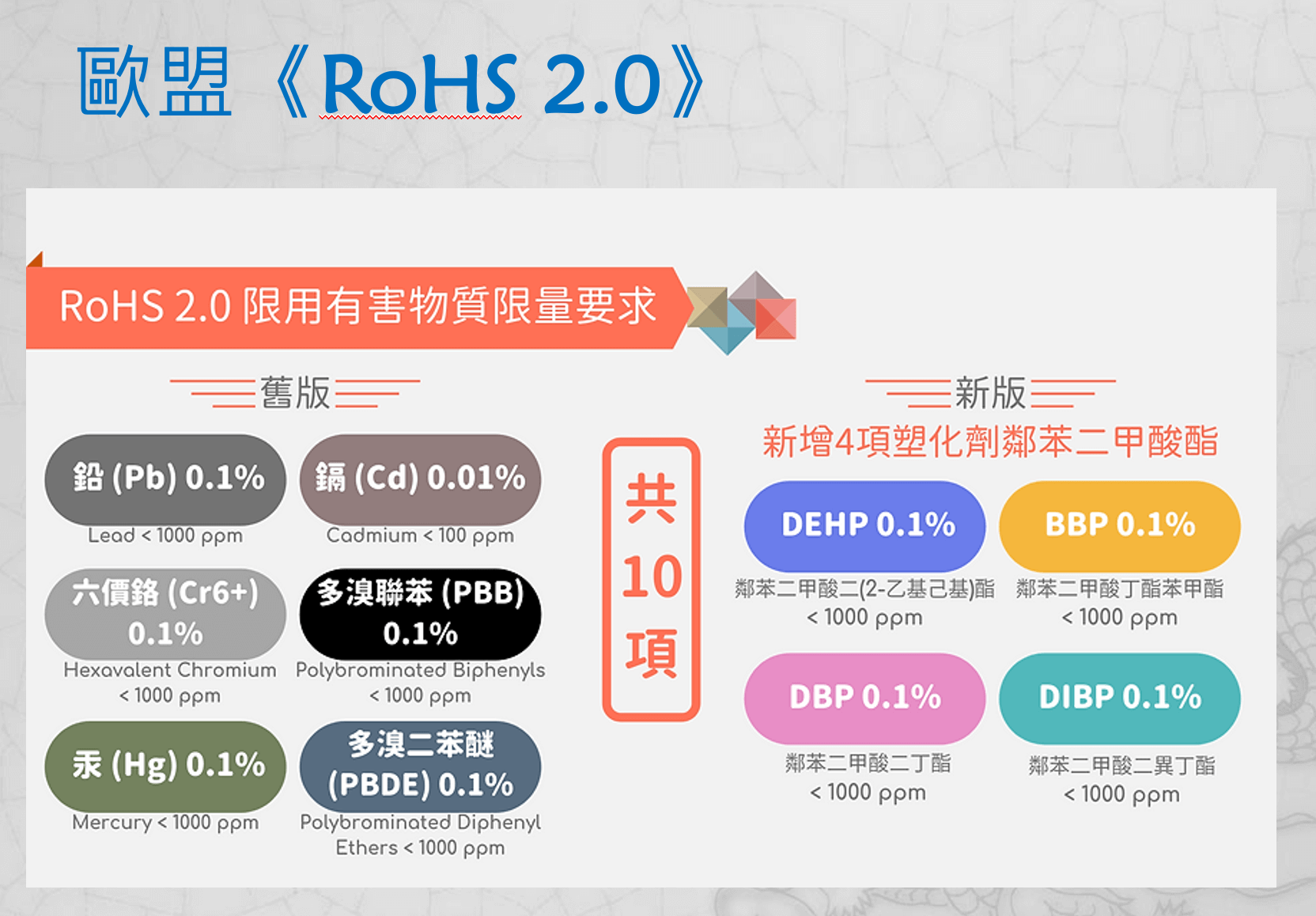

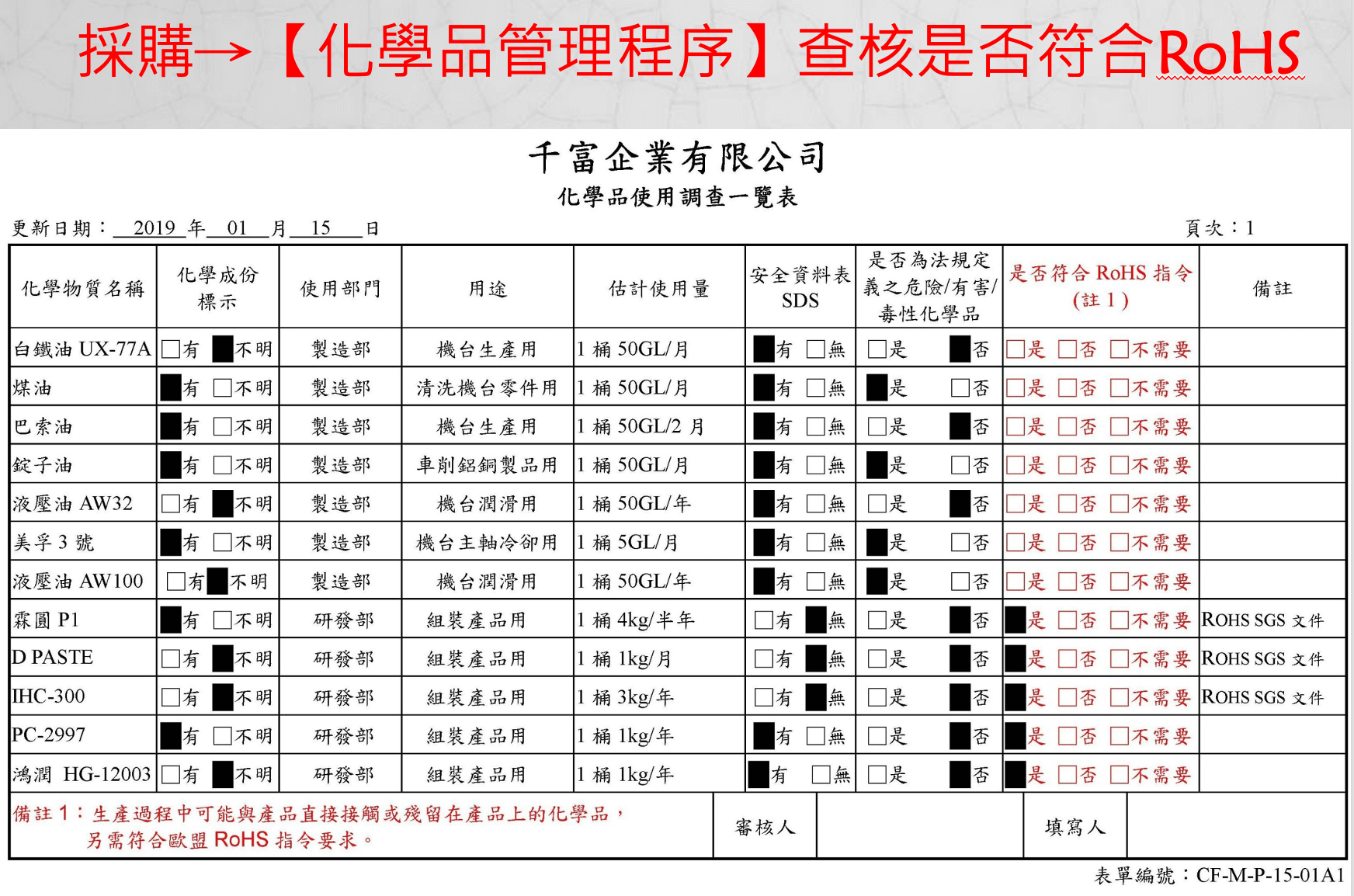

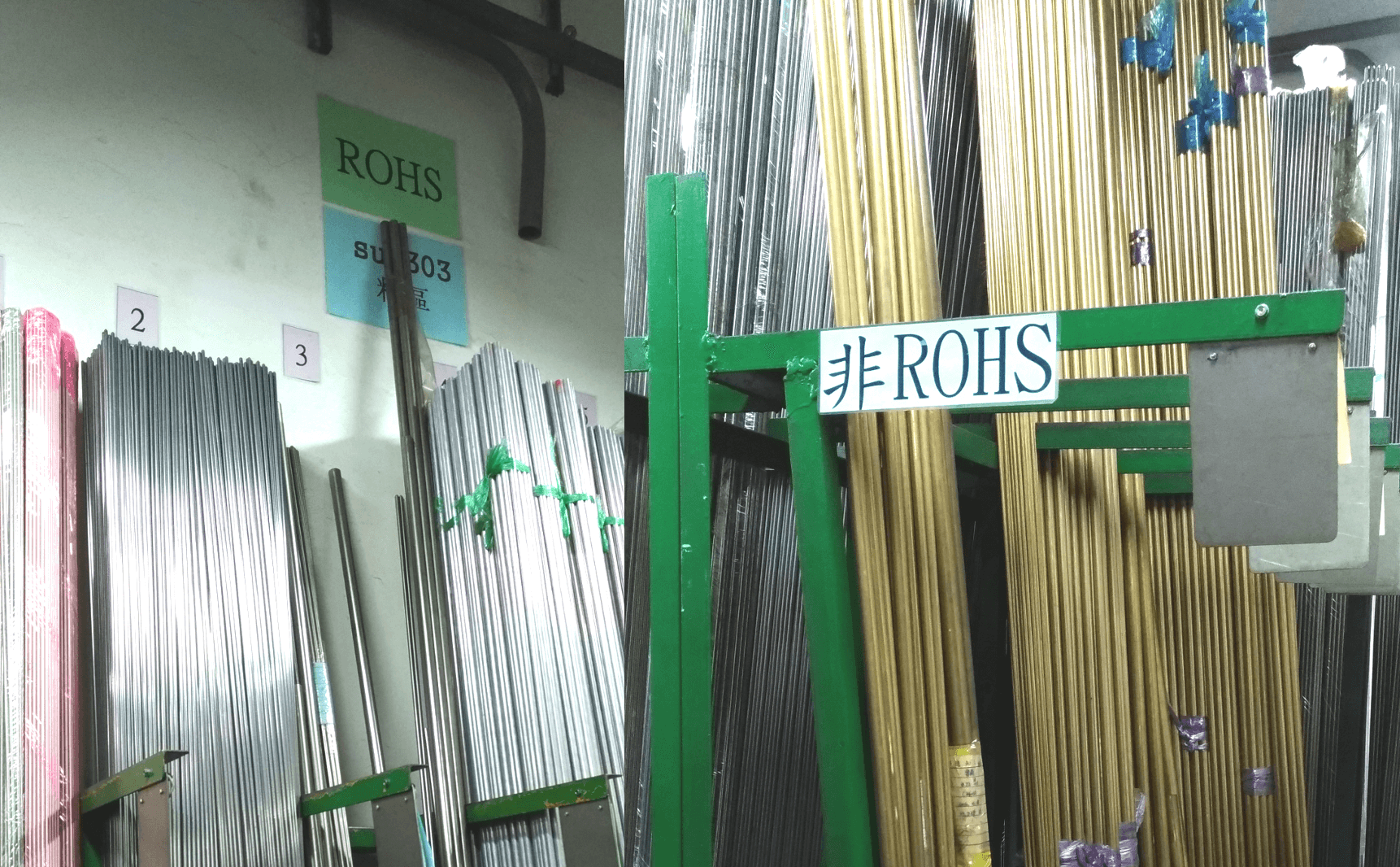

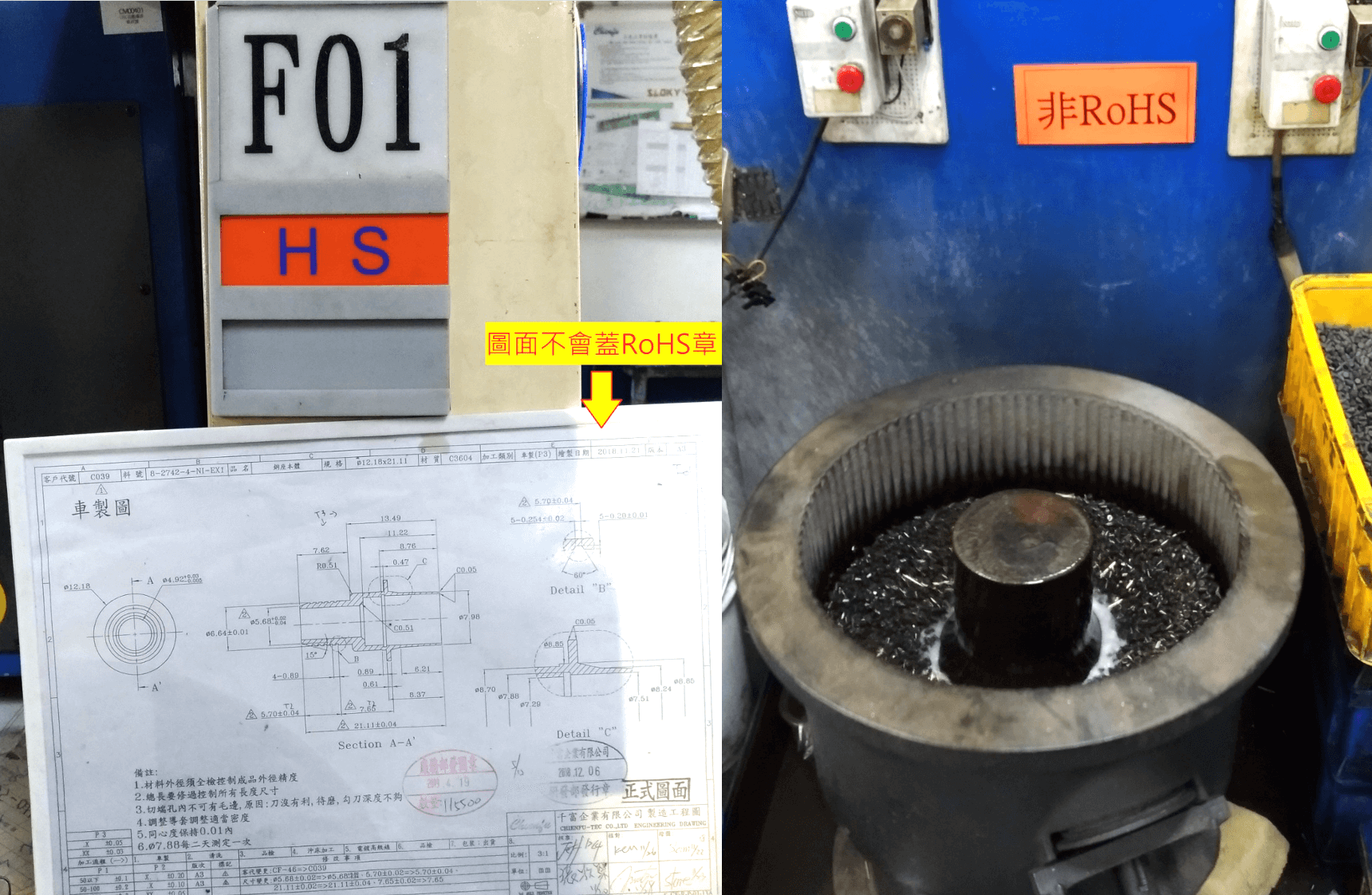

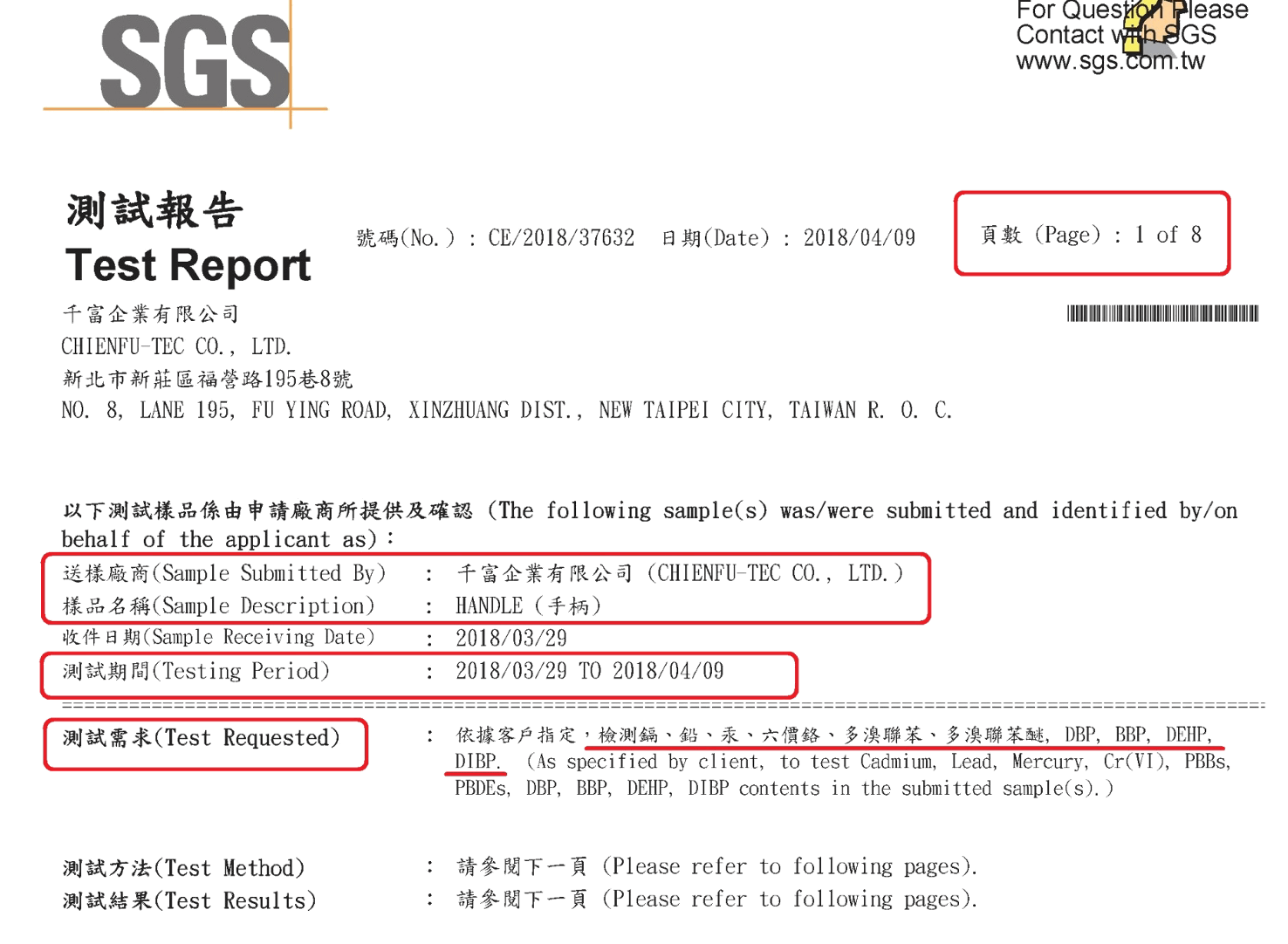

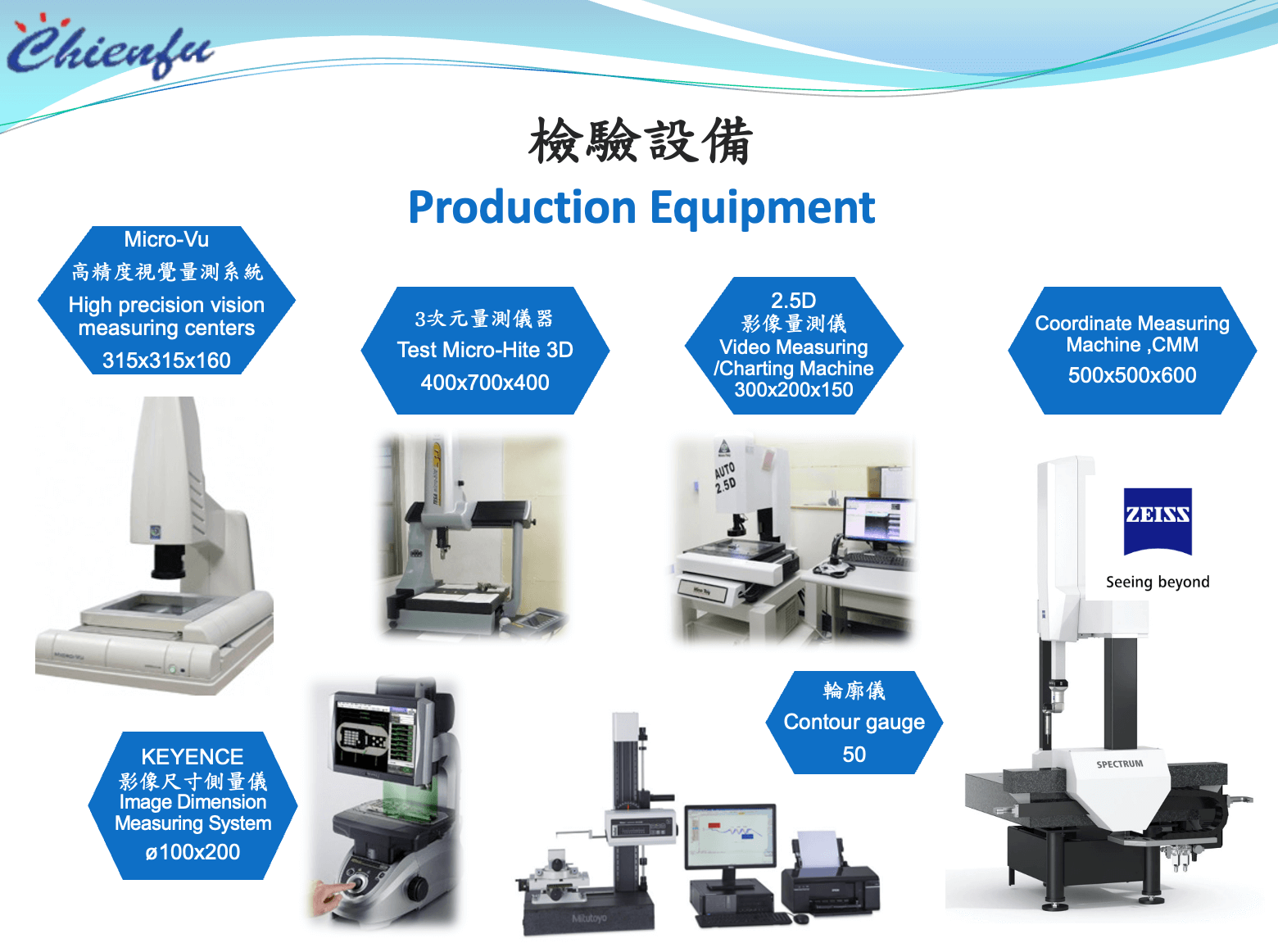

Certifications for Machining Facilities

Different industries have distinct requirements for metal fabrication, making certifications a critical consideration:

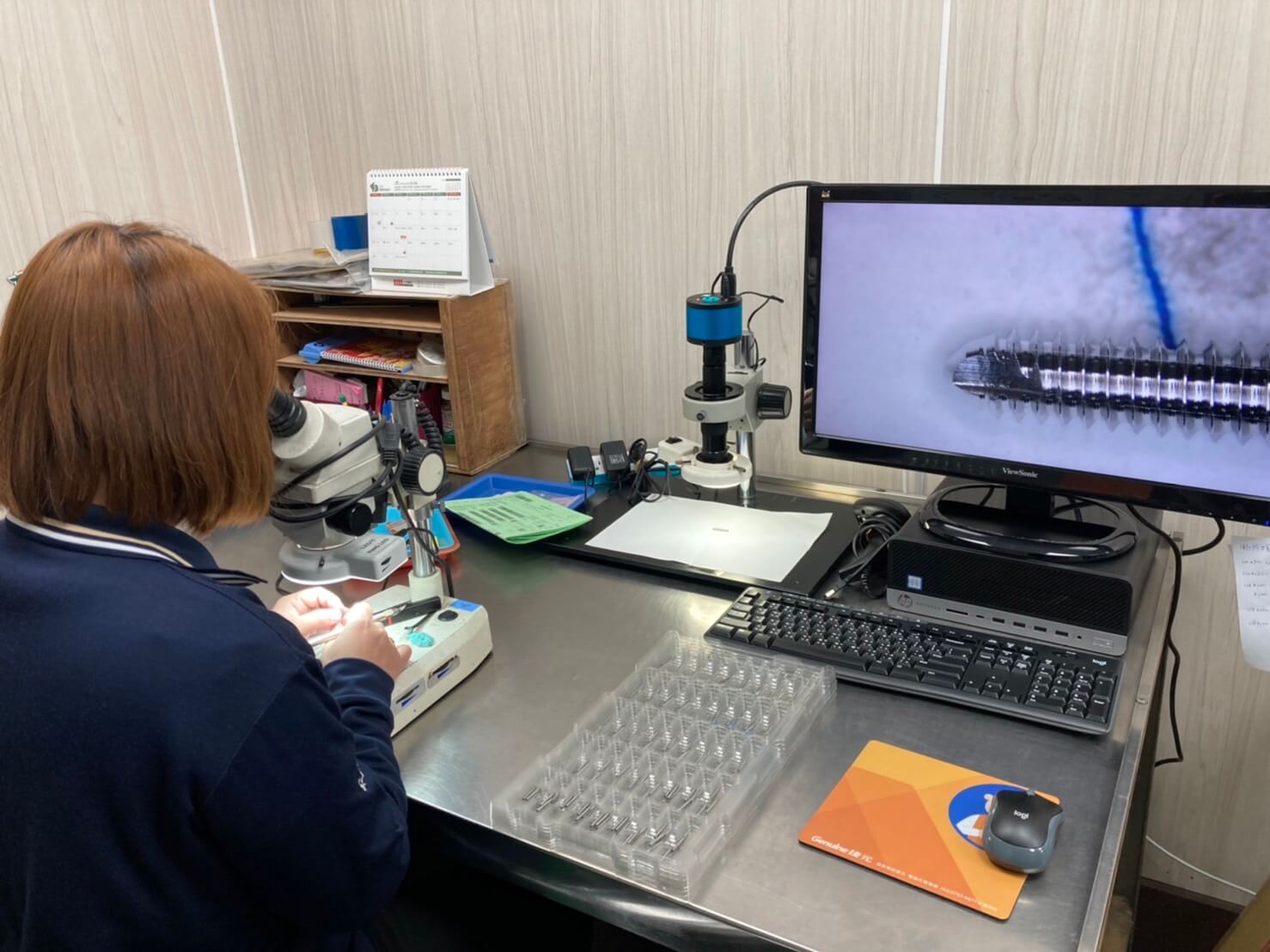

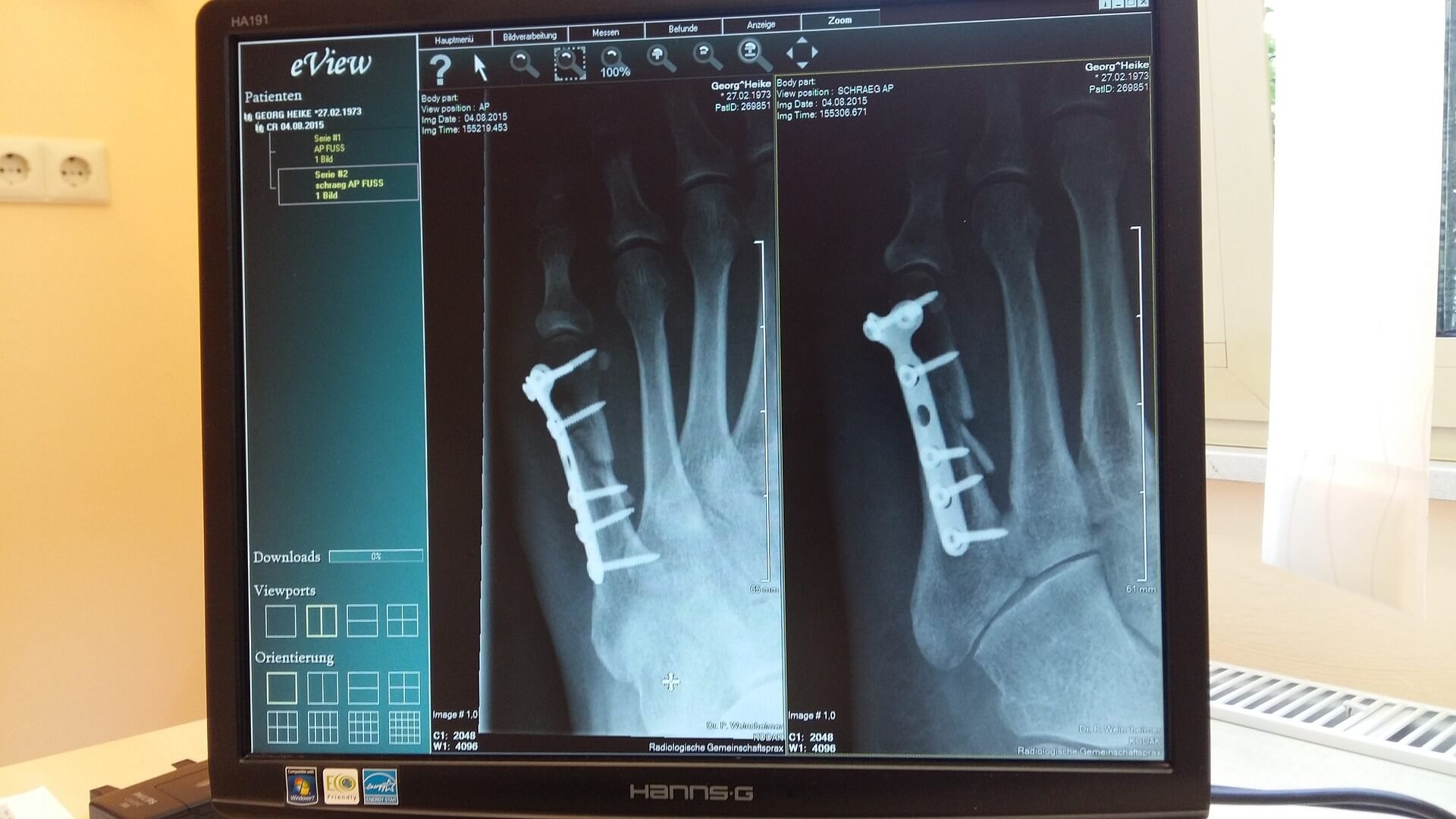

- ISO 13485 for Medical Applications: Essential for manufacturers of medical equipment parts, ensuring adherence to rigorous quality and safety standards.

- ISO 9001 for Quality Management: Fundamental certification indicating robust quality control processes and management systems.

- ISO 14001 for Environmental Sustainability: In an era prioritizing sustainability, this certification ensures manufacturing processes align with environmental standards.

Cost Considerations

While cost remains a pivotal factor, it should be the last consideration. Never compromise on quality, precision, or material integrity. Striking a balance between price and quality without sacrificing either is the ultimate goal.

Conclusion

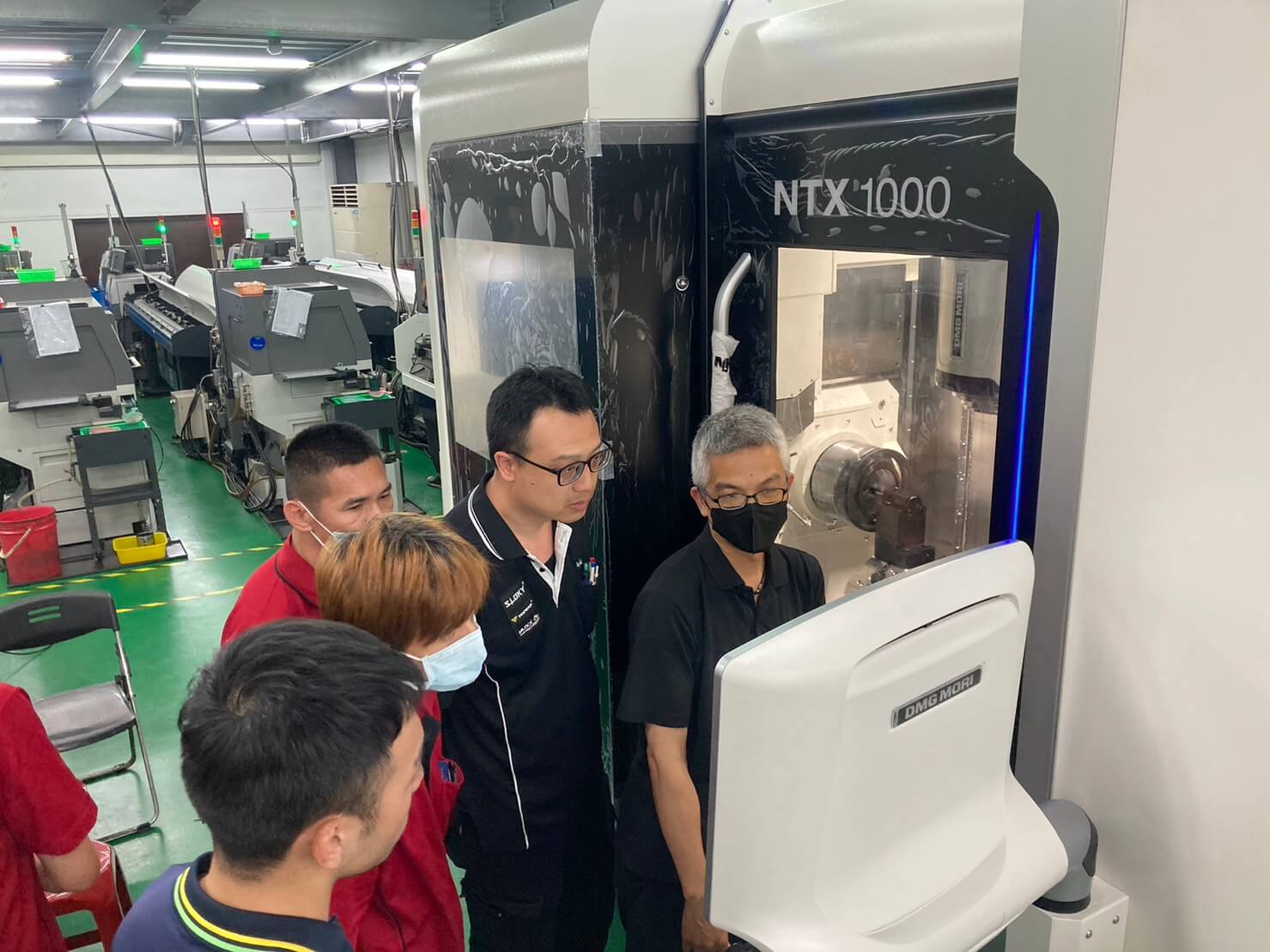

Whether you’re a procurement professional, an engineer with prototyping needs, or a equipment supplier, choosing the right manufacturing partner is crucial. This decision impacts the establishment of a collaborative relationship fostering innovation, reliability, and high-quality products.

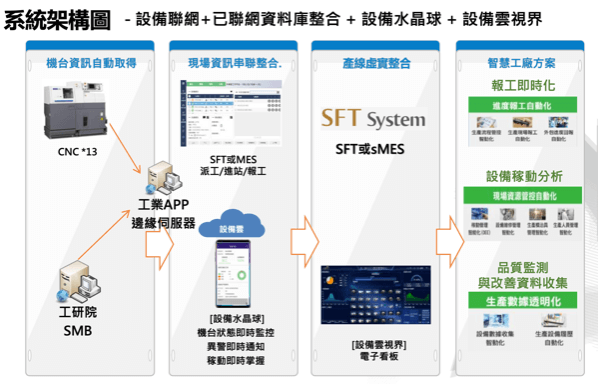

At ChienFu , with over 40 years of CNC machining expertise, we provide end-to-end services from design to machining to packaging. If you have any related needs or questions in CNC machining, feel free to reach out! Our dedicated team is here to assist you!