stainless steel machining

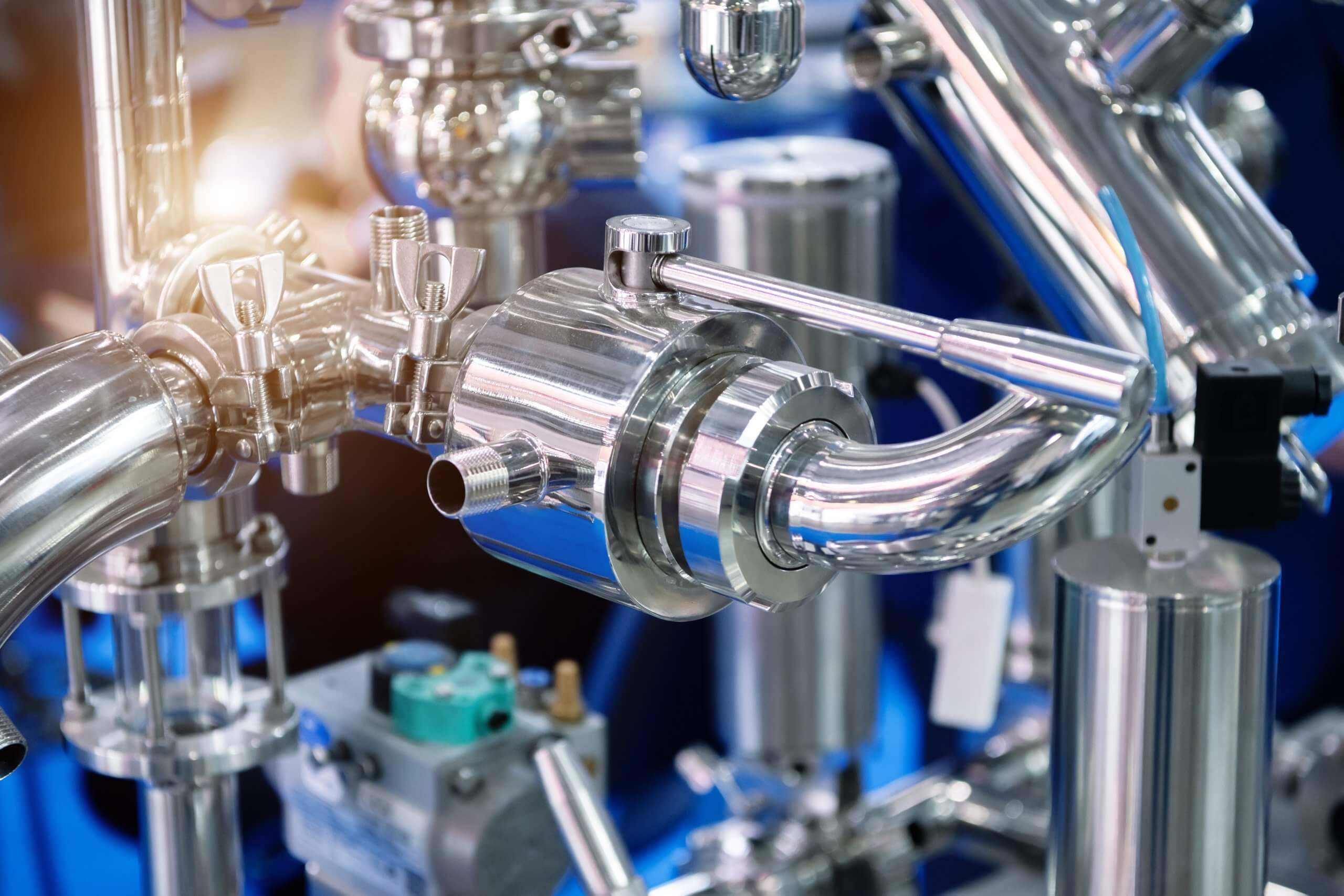

Stainless steel is one of the materials commonly used by customers and suppliers in production and processing. Processing stainless steel is popular because it has multiple grades and offers many advantages and features that make it suitable for a variety of applications. To be classified as stainless steel, it must contain at least 10% chromium, an element that gives stainless steel many unique properties, such as corrosion resistance and the ability to repair itself in front of oxygen.

Stainless steel has many advantages in industrial processing applications, including strength. Stainless steel processing is popular for its superior strength-to-weight ratio, which allows parts to be machined in thinner materials. Since stainless steel can withstand extreme temperatures, its strength can be further enhanced by cold hardening and thermosclerosis processing to achieve the desired application. Highly versatile and flexible. The flexibility of stainless steel makes it as easy to form, weld, cut and process as traditional steel. Sulfur can be added to further increase its forming properties, however stainless steel is generally considered to be the most formable and versatile change, while other alloy structures are often fragile. The combination of the moldability of stainless steel and today’s innovative manufacturing technologies makes it suitable for a wide range of applications.

Corrosion resistance. Stainless steel is highly resistant to corrosion and can be used in a wide range of environments. Low alloy steels are resistant to atmospheric conditions and stainless steel can withstand exposure to acids, chlorides and alkaline solutions. Stainless steel with high chromium content is highly resistant to corrosion.

Low maintenance and durability. Stainless steel is the first choice for industrial processing applications because it requires low levels of maintenance. Steel can also withstand harsh environments and wide temperatures. When measured with other metals, these combined properties produce longer life cycles at cost-effective prices.

Beauty appeal. stainless steel are available on many surface surfaces to create an attractive, present-day exterior.

Stainless steel has greater resistance and longer life cycles than metals such as brass, nickel and titanium, and other metals are more expensive. Non-metallic materials such as plastics, glass and ceramics are weak and less durable, unable to withstand the extreme temperatures and corrosive elements that stainless steel can have, making them less attractive for processing purposes.