The application of titanium metal is the future trend!

Titanium are strong, lightweight, and corrosion resistant; therefore, Titanium CNC machining is used in a variety of industries, including aerospace, medical devices, military, automotive and others.

Why use titanium?

For these reasons why titanium is an incredibly popular material:

- High strength

- Corrosion resistance

- Good strength-to-weight ratio

- Ductility

- Surface treatment options

- Recyclable

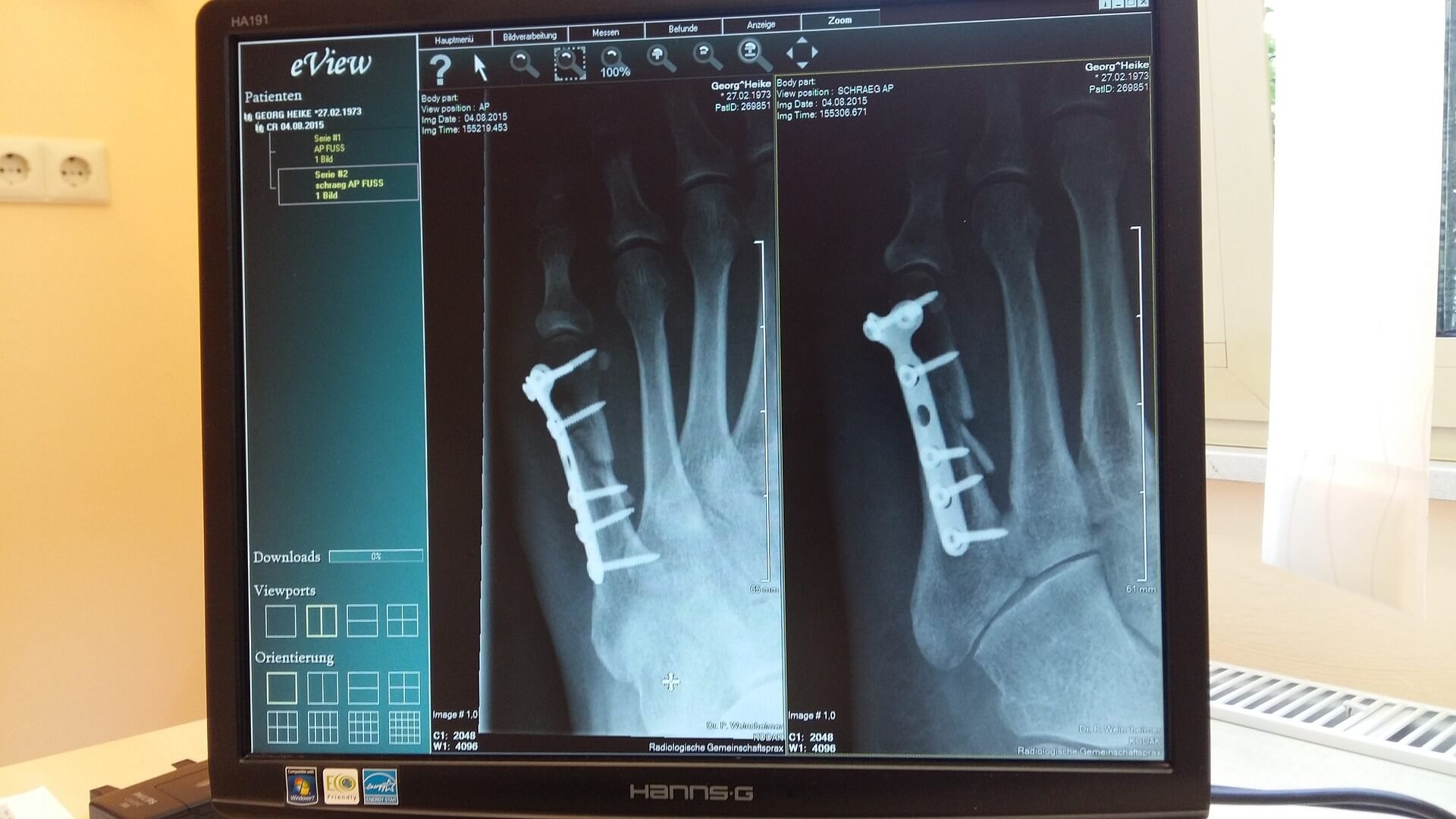

The applications of titanium in aerospace parts include aircraft engine parts, airframe parts, rotors, and compressor blades.For medical application, titanium parts are used for surgical implants (such as long-term hip replacements) and instruments.

The biggest challenges with CNC machining of titanium

It takes more time to adjust CNC machine for Titanium material which ensures a better surface finish and cutting tool life.

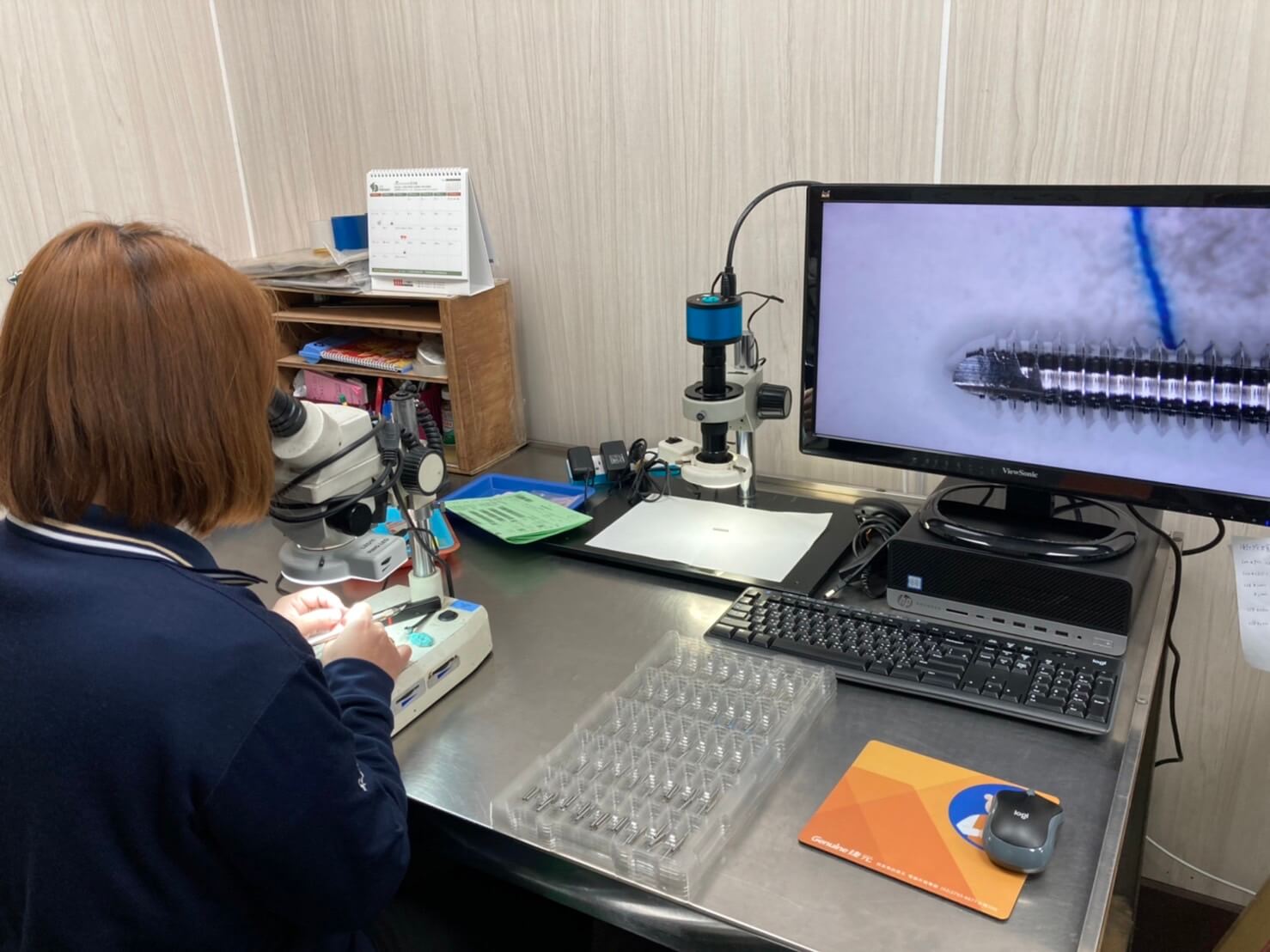

Burrs problem:

It’s impossible to avoid burrs altogether in Titanium processes, we pay attention to removal burrs, because burrs can be consequential to the health of the end user as in the medical industry.

The high requirements for machining titanium by Chienfu

- Manufacturers meet industry standards and regulations for quality and process, such as ISO 13485 and ISO 9001.

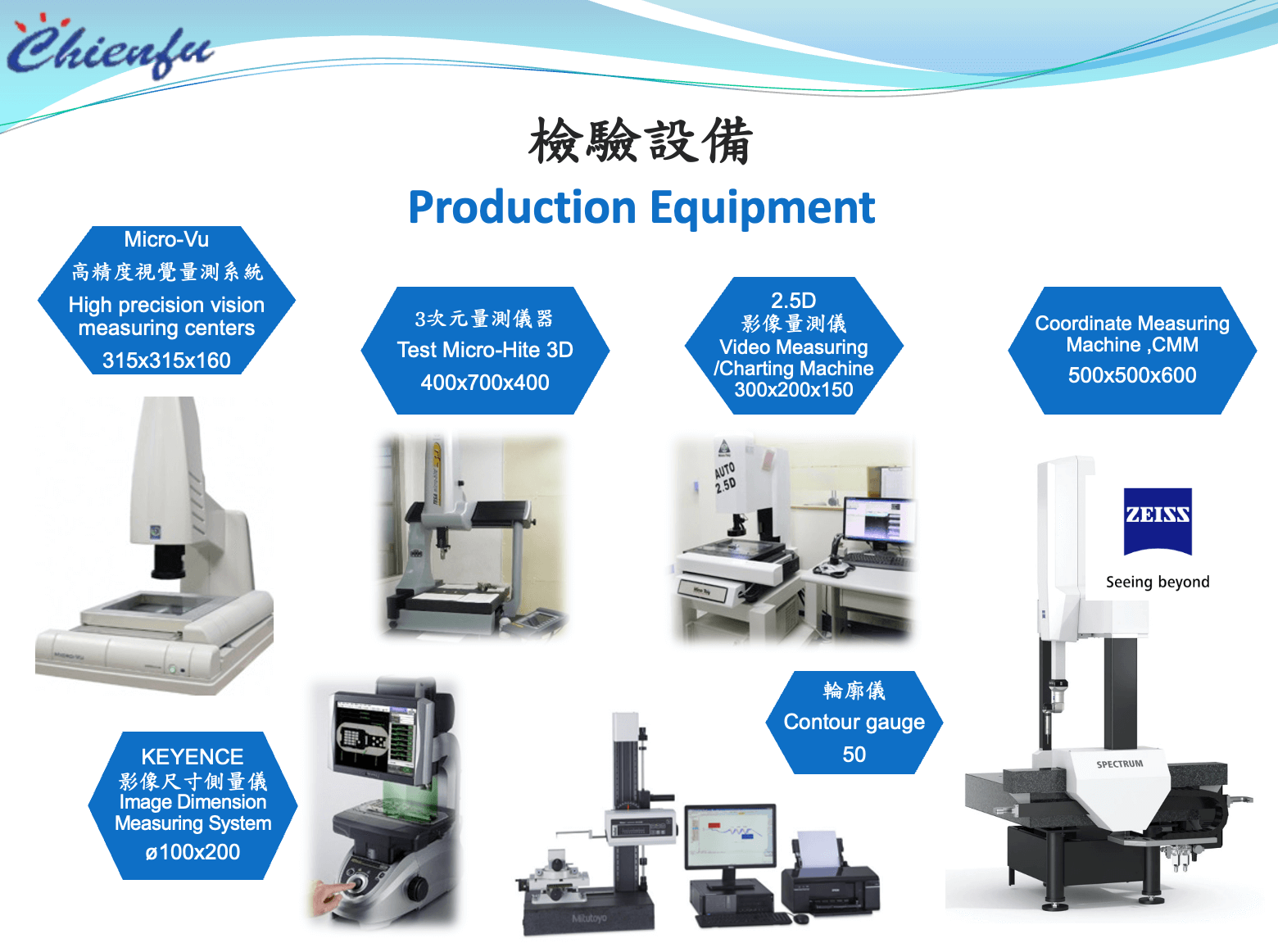

- To ensure quality control, All the titanium product needs to be tested with precision instruments.

Cutting tool problem

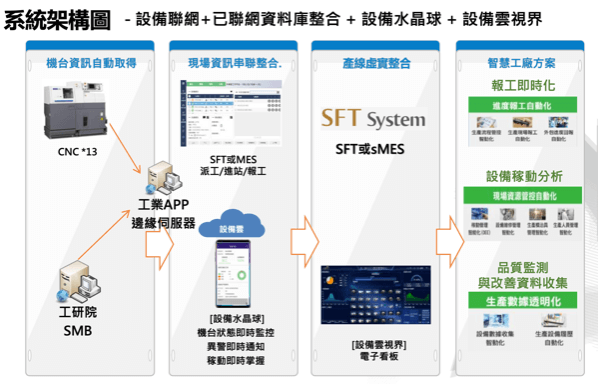

Wearing of Cutting tool can run high when machining titanium alloys which may lead into poor quality. To fix this problem, we have built MES system in ChienFu. With MES systems, Chienfu can replace cutting tool immediately to optimize cutting tool usage and minimize cutting tool wearing off.